MIDDLE AGES (1996 - 2006)

At the beginning of our Middle Ages, Warmpeace seemed to be an ‘experienced company’ with several facilities, a large number of production and non-production employees, and ‘a bit of oomph’, as one of our favourite competitors, Roman Kamler (nowadays Mr. Tilak), once said of us.

In May 1996, we opened a large new shop in Prague and also moved our wholesale stock and company management to the same address. At the time, the shop was considered huge, and it soon became popular among our target group. The problem was that such a large shop called for a wide range of products, high stock levels, investment, time, and attention. The same rang true for the company’s wholesale and import departments. In other words, we enthusiastically threw ourselves into any area of business that seemed fun, and ‘unfortunately’ they all succeeded and required constant attention and commitment. We somehow managed, but it was only a matter of time until we realised that we couldn’t do everything and would have to choose what to focus on and what to let go.

The solution came sooner than we expected. An economic recession, financial measures implemented abroad, customs agreements for suppliers, and a dramatic increase in foreign exchange rates forced our hand. This led to an abrupt and liberating end to our import activities from fellow outdoor brands and freed up funds, time and energy for production and sales activities.

We obviously didn’t want to discontinue something that we had spent so much time developing. We had built up a strong friendship (that is still going strong) with the partners we represented in the Czech Republic, and we were sorry to have to end our cooperation. In the end though, we realised that everything we had learned about distribution would still come in handy and that every end is a new beginning.

Crisis or no crisis, the outdoor equipment market was still thriving. Perhaps it was partly because the political enthusiasm that had initially reigned following the Velvet Revolution was beginning to fade and partly because even the most naive of people (I include myself in this group) were being dispelled of their illusions, but people started to focus on personal experiences, travelling and having a good time in general.

In 1998, the export market suddenly took off for Warmpeace. After years of more or less futile participation in trade fairs in Germany, the West suddenly took notice of us and we gained notable partners in Germany, Denmark and Finland, and the number of countries we were represented in started to grow. The demands that were placed on our little factory soon became impossible and financing the production cost was a nightmare, but we somehow always managed, surviving from hand to mouth.

By the turn of the millennium we had a firm base on the European outdoor market, a line of interesting and popular products, and plenty of satisfied customers. We noticed that our market and everything in it had fallen into a regular mechanical rhythm, regulated by the two seasons that all producers and sellers of outdoor equipment had gradually succumbed to. This set schedule had taught us how to start preparing for each season in good time, to estimate what was to come and to be ready for it. The regular cadence of seasons had unfortunately also let time slip away at breakneck speed, from one season to another, from one trade fair to the next...

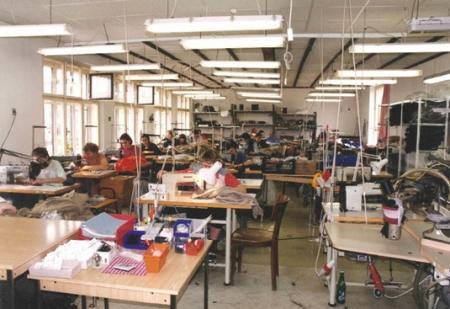

Our production had gradually shifted towards a functional system that finally resembled professional manufacturing. We made up for our lack of capacity by cooperating with other sewing factories. At first in the Czech Republic and Slovakia, and soon also in Asia. In 2001, having spent many years refusing offers from Asian producers that had been ‘trained’ by our large competitors, we plucked up the courage to produce part of our line in the Far East, so off we set to cautiously reconnoitre the situation in Vietnam. Our own factory’s lack of capacity was not the only reason behind this shift; most of our suppliers had already moved the production of fabrics and accessories such as thread to the Far East to be closer to their major customers. European textile factories were therefore closing one after the other, and we suddenly found ourselves buying most of our traditional fabrics from their new Asian branches. The situation being what it was, it was only a small step for us to stop transporting rolls of fabric over such large distances and instead to move production to Asia and transport the finished products. Of course we worried about the quality, and we had no idea how the communication process, or the process in general, would work out. We also had to say goodbye to our previous system, where the fabric was slowly put into production to produce the exact sizes and colours needed at that moment. On the other hand, large production numbers meant lower costs and a lower price per item.

We soon discovered that outsourcing production to factories that specialise in a very specific production category greatly benefits the technical quality of the final product. Specialised producers can afford to invest in special technologies because they will use it for several different customers on a daily basis. In an age where technology improves and changes within months, this just wasn’t an option for our small factory. The shift from producing all our own goods to letting specialists take care of the production process therefore mainly benefited our products and their users. In 2003, we therefore decided to specialise our own production and focus on just one or two categories, while the rest of our range would be produced in more suitable places. This naturally led to us decreasing our capacity, reorganising our facilities and letting a number of our production employees go. It was unavoidable and unpleasant. The worst part was that we didn’t terminate our production entirely; we only reduced it, which meant that we had to choose who would stay and who would go. We knew most of our staff well…

Our production has since expanded around the world, using materials from America, Taiwan, Japan and South Korea, with just a few tweaks to the system here and there.

Towards the end of our Middle Ages, we started to perfect this new system of ours (once again, it was a case of trial and error), from finding suitable factories, through cooperating on putting products into production, to final inspections. Our greatest fear (that we would end up selling products that we had no relationship to) did not happen. Having spent years cooperating with producers abroad, our relationship with the workers there is as close as it is with the seamstresses in our own factory. The goods are still fully ‘ours’. We are incredibly pleased about this and it is another reason for us to continue down this route.